Description

Cuplock Scaffolding Standard – Heavy-Duty Vertical Post for Modular Scaffold Systems in UAE

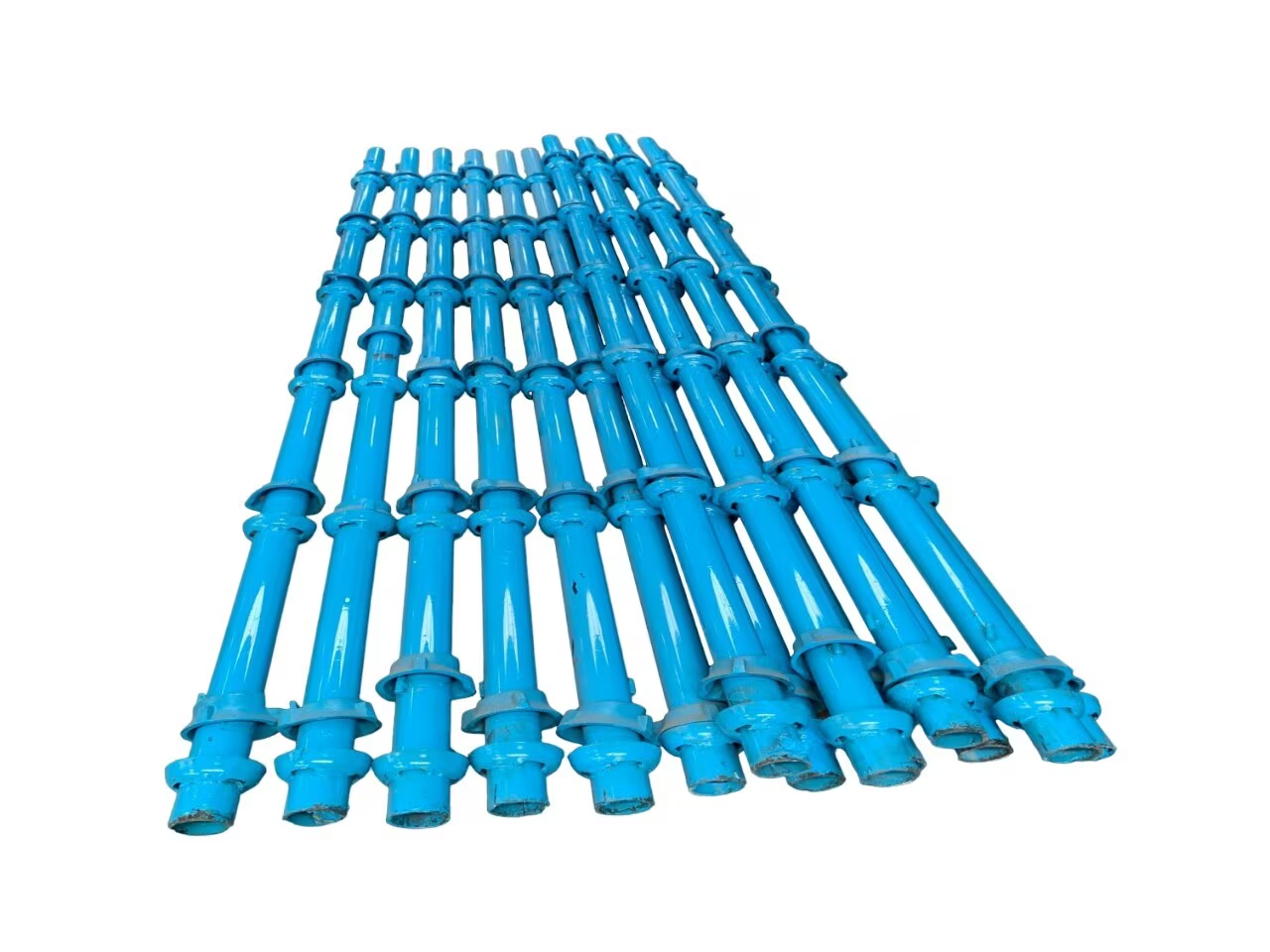

The Cuplock Scaffolding Standard, also called the vertical post or upright, is the backbone of the Cuplock modular scaffolding system. Because it is engineered for exceptional strength and stability, construction crews can assemble and dismantle scaffold structures quickly while maintaining strict safety standards. Moreover, its innovative design ensures reliability in even the most demanding projects.

In addition, each standard is made from high-strength ERW steel tubing with a 48.3mm outer diameter. At fixed 500mm intervals, bottom cups and sliding top cups allow ledgers and transoms to lock firmly into position. As a result, the system removes the need for bolts or nuts, which in turn speeds up installation and reduces labor effort.

Furthermore, the quick-lock cup-and-blade mechanism guarantees accurate alignment at every scaffold level. Crews can therefore adapt it easily for complex configurations—for example, high-rise façade access, heavy slab support, or industrial maintenance platforms. Similarly, it works effectively for bridge scaffolds and formwork structures.

The steel is either hot-dip galvanized or painted, offering long-term protection against corrosion. Consequently, the Cuplock standard performs reliably in both coastal and inland UAE environments, even under extreme weather. In fact, many contractors prefer it for projects with long timelines and high durability demands.

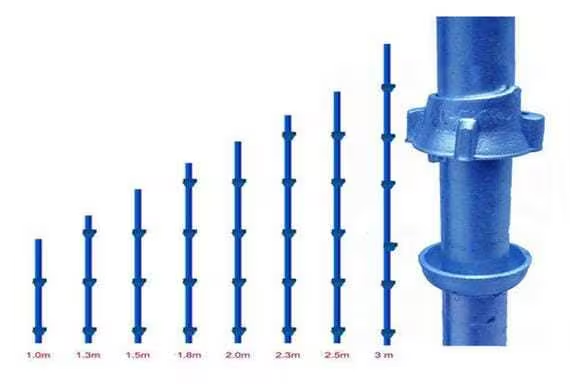

Not only does it offer exceptional load capacity, but it also comes in multiple lengths—from 0.5m to 3.0m—ensuring adaptability across various projects. Therefore, it is equally suited for bridge construction, formwork systems, and infrastructure scaffolds where precision and strength are essential.

Key Features of the Cuplock Scaffolding Standard

- High Load Capacity: Supports heavy vertical loads in modular scaffold systems.

- Quick Assembly: Cup joints every 500mm enable tool-free connections.

- Heavy-Duty Steel: ERW steel tube construction maximizes load resistance.

- Corrosion Resistant: Painted or hot-dip galvanized for long life.

- Flexible Sizing: Multiple lengths suit diverse project requirements.

- Enhanced Safety: Bolt-free locking system ensures secure setup.

Applications of Cuplock Standards

- Building façades and perimeter scaffolding.

- High-rise slab and beam support structures.

- Formwork and shuttering in civil projects.

- Industrial maintenance and plant access scaffolds.

- Infrastructure, bridge, and transport projects.

Technical Specifications

- Tube Diameter: 48.3mm OD

- Wall Thickness: 3.2mm (customizable)

- Node Points: Every 500mm

- Material: Steel

- Standard Sizes: 0.5m, 1.0m, 1.3m, 1.5m, 2.0m, 2.5m, 3.0m

- Finish: Painted / Hot-dip galvanized

- Connection: Fixed bottom cup + sliding top cup